The manufacturing sector is one of the most strongly performing industries in the UK at present, with firms experiencing a high level of demand both domestically and overseas. This has contributed hugely towards the UK’s economic recovery, creating jobs and growth in many regional areas.

Now, the government has revealed it plans to further boost UK aerospace manufacturing with a £15 million cash injection to create a national centre for 3D printing technology at Ansty Park, Coventry.

A further £15 million will be invested into extending existing aerospace operations on the site, which is already one of the country’s leading aerospace manufacturing facilities.

Chancellor George Osborne expects that the £30 million of public money will be matched by private investors, bringing the total expansion capital to £60 million overall.

This would significantly build upon a previous government funding scheme of £18 million, announced last November, which will be used to create an “elite” technology training centre at Ansty Park.

The new printing facility will be based at the site’s Manufacturing Technology Centre and will specialise in the creation of products for aero-engines and aircraft landing gears. However, researchers are also interested in developing parts for automotive and medical devices.

Chief executive for the Manufacturing Technology Centre, Clive Hickman, believes that the government’s investment will contribute significantly towards site expansion and further recruitment.

He says; “It’s been bubbling for the last five or so years – now it’s become important for the industry and for the future.

“This investment is going to help us maintain our lead and will translate into jobs.

“It’s quite a slow process at the moment but we’re working with some very powerful lasers here: it’s game changing for the industry.”

The Manufacturing Technology Centre opened in 2011, and announced that it would employ at least 250 workers by 2014. However, with this latest investment, it seems that even more positions will be created in order to boost the growth of manufacturing, with Mr Osborne claiming “high skilled, long term” jobs are the goal.

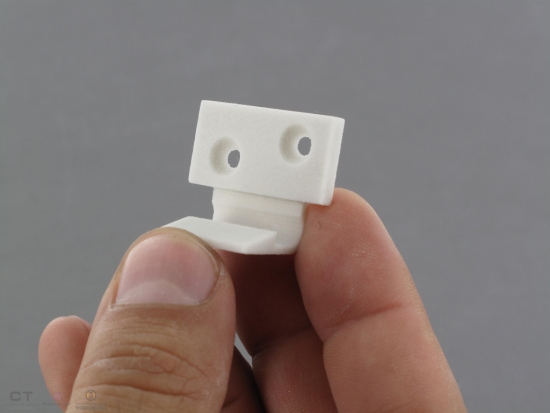

3D printing technology is relatively new but is seen as a revolutionary step in manufacturing. Industry experts believe the process to be the next step in cost management during the manufacturing process, as it requires fewer materials to create parts for a range of products.

So far, smaller parts such as bolts and screws are the most common products of the 3D printing process, but technicians have been known to create electric guitars, engine components and even clothing and footwear items whilst testing the limits of the technology. NASA has already incorporated the device into its operations, using 3D printed rocket parts in test missions.

With the UK aerospace manufacturing sector forever seeking ways in which to expand and improve, it seems that 3D printing will test once and for all the theory that “the sky’s the limit”.